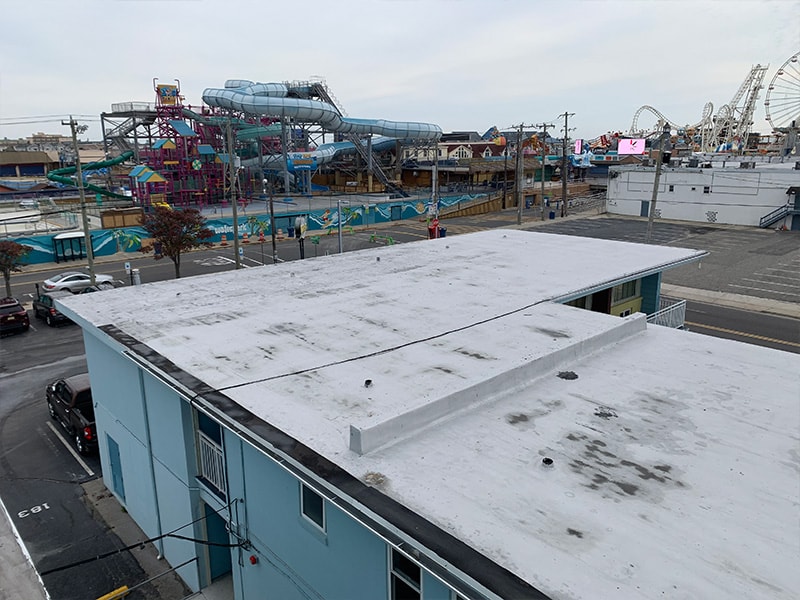

Project Description

This 143 sq roof was able to be restored with a liquid membrane rather than a costly tearoff. Partially reinforced perimeters, seams and around penetrations. Areas were ponding water were present were built up prior to coating.

The roof was dry broomed then powerwashed and let to dry before our Armour Proof Coatings system was applied.

Surface Preparation

The contractor cleaned the roof with brooms to remove dust and larger debris and then power-washed the surface to remove any loose coating and caked on debris to prepare the roof for the liquid membrane system.

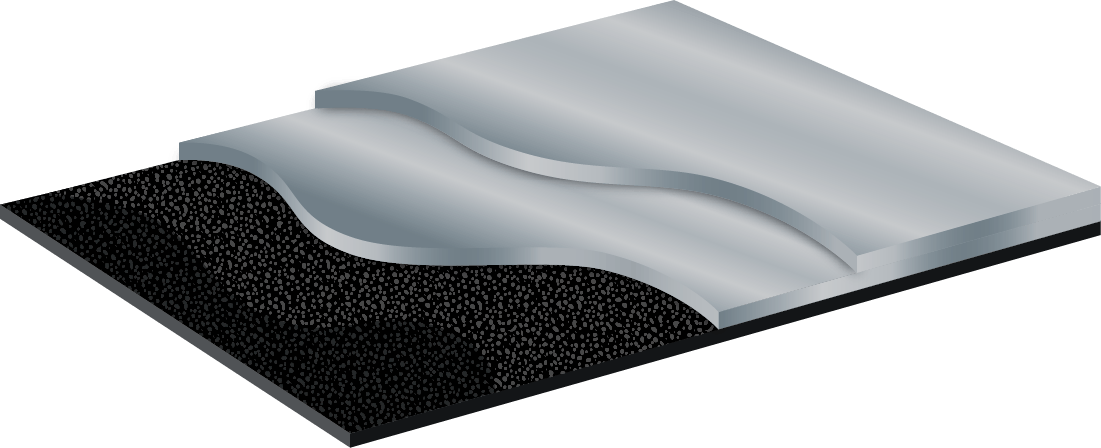

Seam & Penetration Repair

The seams and penetrations were reinforced with our 12” Polyester Fabric embedded into AP-5100 Moisture Cure Polyurethane to protect to these vulnerable areas.

System Coating Process

2 coats of AP-5100 Moisture Cure Polyurethane were applied to the entire roof, providing a reflective, monolithic membrane surface.

System Benefits

- 350% Elongation

- Adheres to Most Substrates

- Great UV Protection

Finish coat of AP-5100 Moisture Cure Polyurethane Roof Coating

More Case Studies

Check out some more projects. Get inspired! See how your building could be transformed for years of service extension and then get in touch with your local rep to get started!

Grow Your Roofing Business

Become an approved applicator of our Armour Proof Coatings systems and gain the perks of being a trusted and approved contractor. Benefits include project referrals, marketing assistance, product trainings & more!